Update: Please read the comments section of this post for the latest on this device.

Thanks to a combination of poor time management on my part and digging up an absolutely crucial road at rush our on the part of Hull Council I wasn't able to get to the MeetUp at C4DI tonight. But when I did get home I thought I'd fire up the iBox nano printer that arrived last week.

The printer was a Kickstarter project. I've had pretty good success with Kickstarter. I've only had one Kickstarter project come seriously unstuck - I'm looking at you Agent watch. The iBox project promised a light powered high resolution printer for less than 300 dollars and was too tempting to pass up. So I backed it a while ago (I think it was November) and then waited.

The device was a bit late arriving, but I don't mind too much about that. Lots of people get very upset when these projects have delays, but I'm happy to give them time to get it right. As long as something turns up at the end. I'm still looking at you Agent watch....

The iBox is powered by a Raspberry Pi and uses a WiFi adapter to connect to your network. You set up prints on your PC via a web interface that works really well. There are a few buttons on the machine and some lights to tell you what it is doing.

So I carefully filled the vat with resin, rubbed the build plate with some sandpaper to make it nice and rough so that the print would adhere to it, lowered the plate into the resin and set it off.

My first print failed. All I got was a little lump of goo on the bottom of the vat. Oh well. I've got quite good at consistent printing with Una my Ultimaker, but I remember how much fiddling it took to get to where I am now.

It turns out that, just as with Una, the key to successful printing is the print height. When Una squirts molten filament at the build plate it is crucial that the very first layer is just the right height for the filament to stick to the plate and provide the starting point for the print. With my iBox printer, which doesn't have a name yet by the way, the crucial thing is the distance of the build plate from the bottom of the glass dish, or vat, which holds the liquid resin.

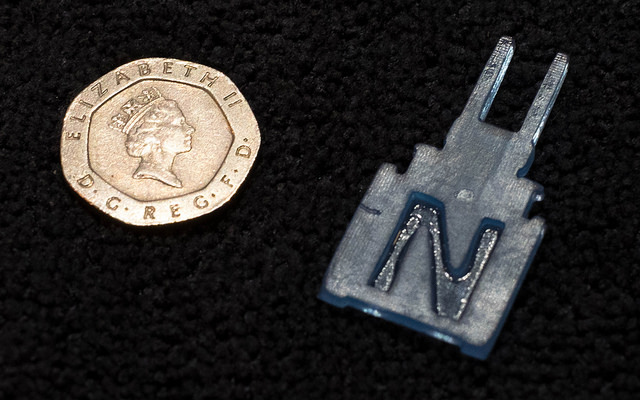

The idea is that the build plate is a tiny distance from a sheet of teflon tape stuck on the bottom of the vat. The UV light makes some of the liquid resin in this gap turn solid. Then the printer pulls the build plate upwards, taking this layer of solid resin with it. Only on my first print the solid bit stuck to the bottom of the vat instead, hence the mis-shapen lump that was produced. So I re-adjusted the build plate and tried again.