Ringing a bell is surprisingly complicated

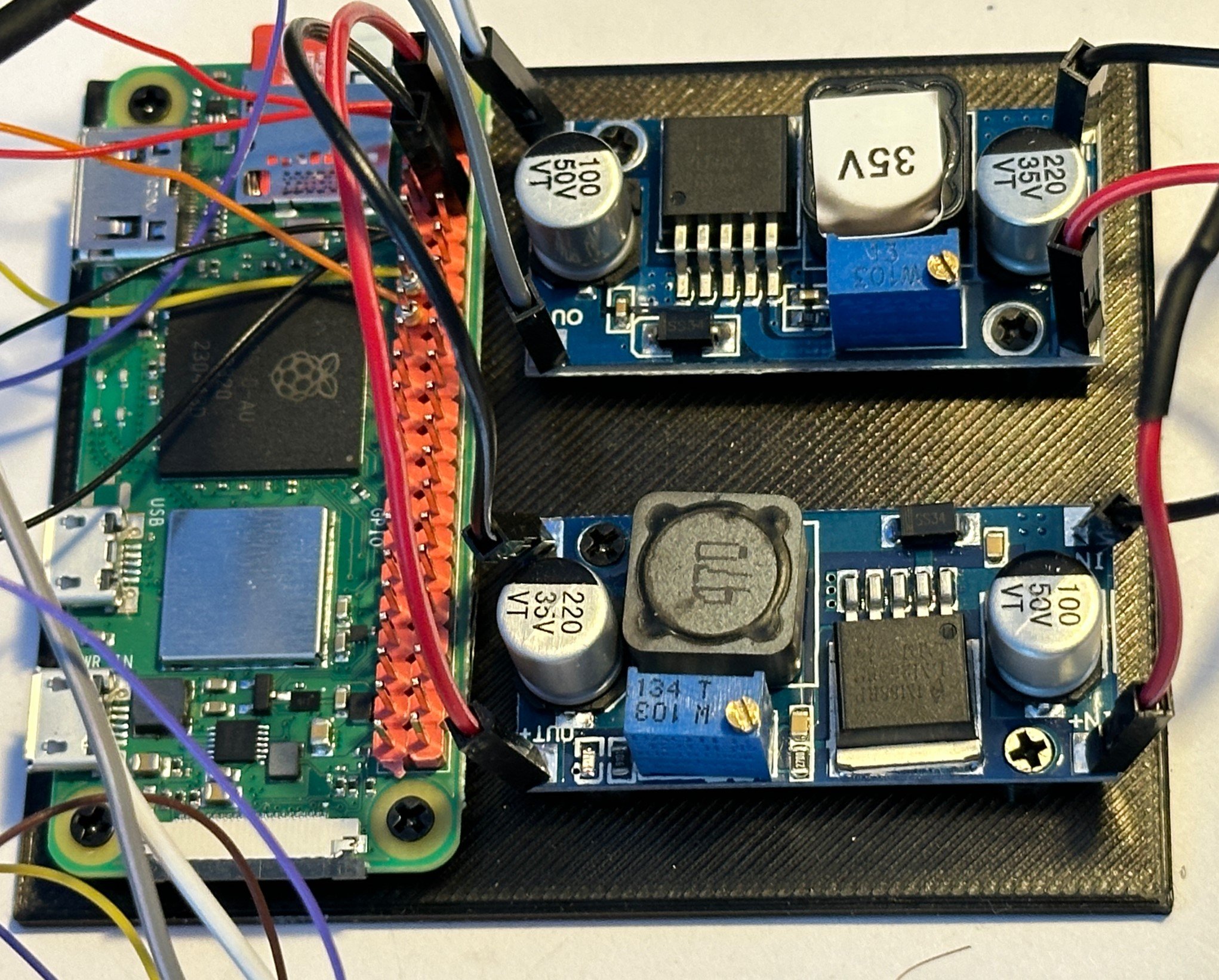

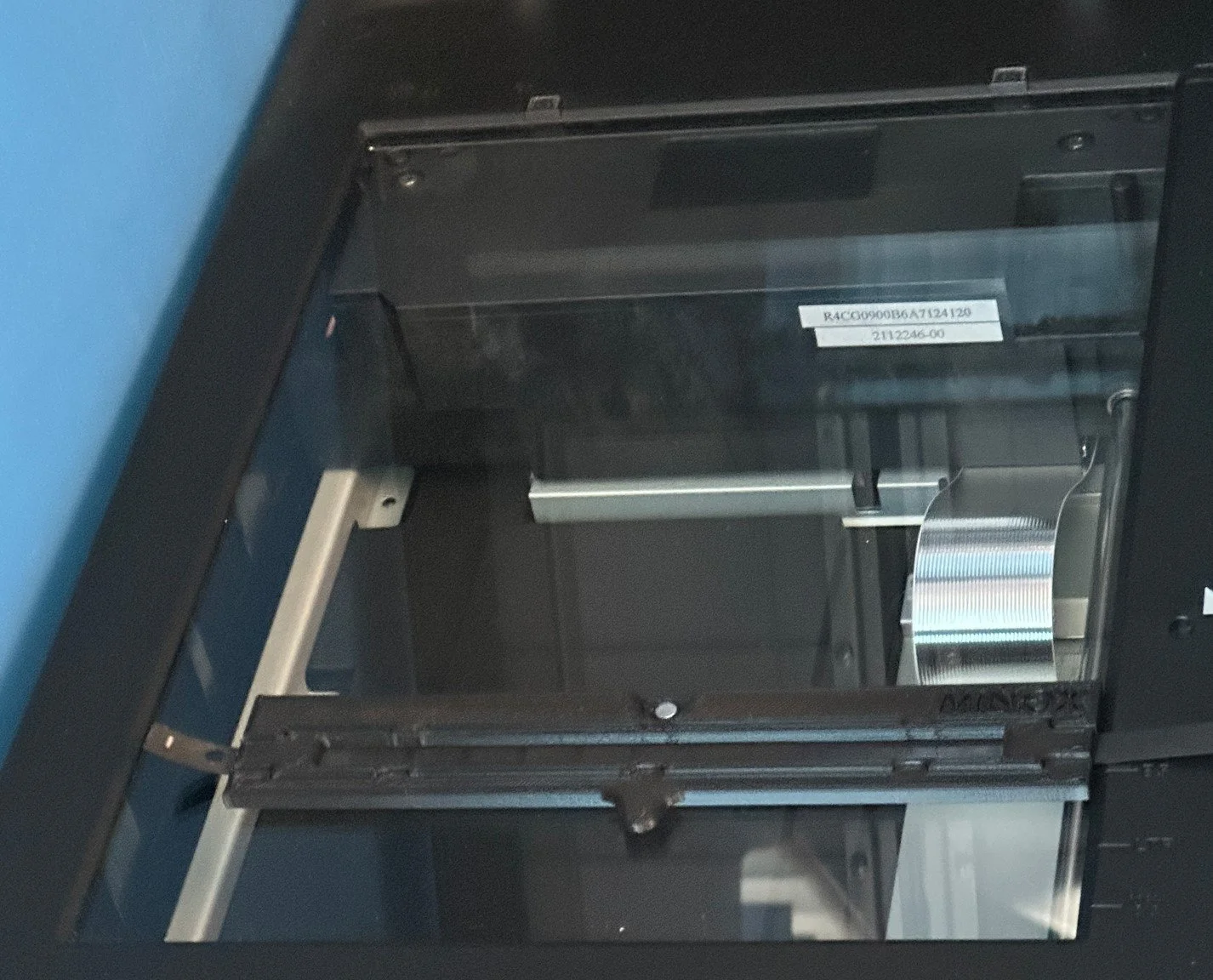

/def ding(self):

# start the clapper moving towards bell 1

GPIO.output(self.bell1GPIO, GPIO.HIGH)

time.sleep(0.016)

# stop the clapper moving

GPIO.output(self.bell1GPIO, GPIO.LOW)

# pull the clapper back from bell 1

GPIO.output(self.bell2GPIO, GPIO.HIGH)

time.sleep(0.01)

# leave the clapper in the middle

GPIO.output(self.bell2GPIO, GPIO.LOW)

# let the bell ring for a while

time.sleep(0.01)

# start the clapper moving towards bell 2

GPIO.output(self.bell2GPIO, GPIO.HIGH)

time.sleep(0.016)

# stop the clapper moving towards bell 2

GPIO.output(self.bell2GPIO, GPIO.LOW)After a bit of experimentation I’ve managed to make the bell in the old telephone sound realistic. The original bell was just fed with 70 volts AC alternating at 18 cycles a second. The code above triggers the two coils in the bell to allow it to make do with 35 volts. It was quite fun to write. I hope the neighbours don’t mind the way that I seem to be getting a lot of phone calls…….